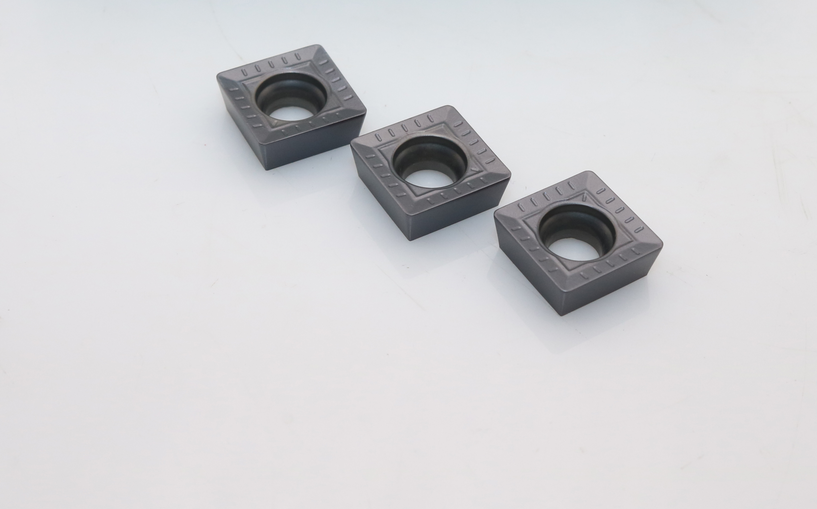

Long Tool Life Carbide Milling Inserts TiCN Coated For Milling CNC

Cutter

Product features

Solid carbide tools offer long tool life and faster cutting speeds

than other substrates, but are more brittle and must be used with

rigid toolholding systems

Multi Layer coating TiC/Al2O3/TiN

Good toughness, high strength in use and versatility for roughing,

medium roughing of steel, alloy steel and cast-iron, especially for

high speed and quick cutting

Use for slotting and slab or straddle milling

Technology:

1. Incorporate latest molding, coating, edge preparation,and other

manufacturing technology.

2. Coatings provide highpeed capability and are engineered from

finishing to hevy roughing,the ostcoat treatment reduces coating

stresses,improves coating adhesion,and improves workpiece finish.

3. Application areas: Machining of cast iron, nonferrous alloy,

chill cast iron, hard steel, stainless steeland other non-metallic.

GRADE TABLE

| Grade | Coated | Application |

| YBC151 | CVD | P05-P20, finishing of P-type material |

| YBC152 | CVD | P05-P20, finishing of P-type material |

| YBC251 | CVD | P10-P30, semi-finishing of P-type material |

| YBC252 | CVD | P10-P35, semi-finishing of P-type material |

| YBC351 | CVD | P20-P40, roughing of P-type material |

| YBM151 | CVD | M05-M30, finishing, semi-finishing and roughing of M-type material |

| YBM153 | CVD | BEST CHOICE for Roughing of M-type material |

| YBM251 | CVD | M10-M30, semi-finishing and roughing of M-type material |

| YBM253 | CVD | M10-M35, semi-finishing and roughing of M-type material |

| YBD052 | CVD | K05-K15, finishing of K-type material, esp. for high speed dry

machining of gray cast iron |

| YBD102 | CVD | K05-K20, finishing of K-type material, esp. for high speed

machining of Nodular cast iron |

| YBD151 | CVD | K05-K25, finishing of K-type material, semi-finishing of K-type

material |

| YBD152 | CVD | K05-K25, finishing and semi-finishing of K-type material |

| YBD252 | CVD | K15-K35, semi-finishing and roughing of K-type material |

| YBG102 | PVD | K01-K10, S10-S20, finishing of K.S-type material |

| YBG105 | PVD | finishing and semi-finishing for materials difficult to cut |

| YBG202 | PVD | P10-P30, M10-M30, K10-K20, S20-S30, semi-finishing of P, M, K-type

material; Roughing of S-type material |

| YBG205 | PVD | M05-M30, semi-finishing and roughing of M-type material |

| YBG302 | PVD | P10-P40, M10-M30, K20-K40, S20-S30, semi-finishing and roughing of

P.M.K.S-type material |

| YNG151 | Uncoated Cermet | P05-P20, M05-M20, K05-K20, wide application in finish machining of

P. M. K-type material |

| YNG151C | Coated Cermet | P01-P20, M01-M20, K01-K20, wide application in finish machining of

P. M. K-type material |

| YC10 | Cemented | P05-P20, finishing of P-type material |

| YC40 | Cemented | P20-P40, rouging of P-type material |

| YD051 | Cemented | K05-K15, finishing of K-type material |

| YD101 | Cemented | N05-N30, S05-S15, finishing and semi-finishing of H-type material,

finishing of S-type material |

| YD201 | Cemented | K10-K35, semi-finishing and rouging of K-type material |

1) Professional and experienced for carbide inserts and cutting

tools

2) Top quality, with high precision and perfect working performance

3) Better and better service with competitive price

4) Quick delivery: 7 Days ( in stock)

5) Full range of cutting tools, turning, milling, threading,

parting&grooving, boring.....

Features:

1. Large production and reliable after service

2. Best technical assistance

3. High hardness, High efficiency, high stability

4. Professional inspection and high precision

5. High precision, easy replacement, general use

6. Moderate price, good quality, short delivery time

7. Support OEM service