Description:

It is an important tool for machining in CNC machining, its purpose

to prevent tools from shanking and to control, which also called

CNC extension rod. With the development of CNC precision machining,

CNC machining from 5000 rpm, 6000 rpm to 8000 rpm may reach more

than 20,000 rpm. At this cutting speed, only the use of

anti-vibration boring bar can achieve high-speed cutting

requirements.

Application:

Its purpose is to prevent tool shaking and control.

This is very important for CNC and machining industry.

Features of solid carbide bar:

1. High rigidity.

Improve surface finish and perpendicularity. Made of pure tungsten

carbide material, excellent rigidity, good shock absorption, no

distortion as lateral stiff-ness too large.

2.High percision.

Improve dimensional precision. To extend the processing depth,

enhance the accuracy of processing and to achieve long, ultra-deep,

ultra-high precision machining possibilities.

3.High efficinecy.

No welding fracture concerns, emphasizing the variability of the

replaceable tool head, a carbide bar can reach dozens of

combinations, widely used in rough and precision processing

industrial.

4. Reduce cost.

Extending the tool life. The holder can be reused even if the

cutter is damaged and easy and convenient to replace.The tip and

the holder are screwed and run in reverse direction to the

splindle.

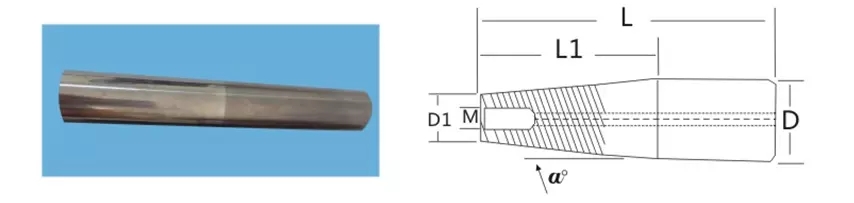

Customized Carbide Screwed Boring Bar:

| Specification | D (mm) | D1 (mm) | L | L1 | M |

| MFT10-50-150-M6 | 10 | 9.5 | 150 | 50 | M6 |

| MFT12-50-150-M6 | 12 | 11.5 | 150 | 50 | M6 |

| MFT16-50-150-M8 | 16 | 15.5 | 150 | 50 | 8 |

| MFT16-50-200-M8 | 16 | 15.5 | 200 | 50 | 8 |

| MFT16-70-250-M8 | 16 | 15.5 | 250 | 70 | 8 |

| MFT16-85-120-M8 | 16 | 15.6 | 120 | 85 | 8 |

| MFT16-95-150-M8 | 16 | 15.6 | 150 | 95 | 8 |

| MFT16-145-200-M8 | 16 | 15.6 | 200 | 145 | 8 |

| MFT20-40-100-M10 | 20 | 19.6 | 100 | 40 | 10 |

| MFT20-90-150-M10 | 20 | 19.6 | 150 | 90 | 10 |

| MFT20-140-200-M10 | 20 | 19.6 | 200 | 140 | 10 |

| MFT25-40-100-M12 | 25 | 24.6 | 100 | 40 | 12 |

| MFT25-85-150-M12 | 25 | 24.6 | 150 | 85 | 12 |

| MFT25-135-200-M12 | 25 | 24.6 | 200 | 135 | 12 |

| MFT32-70-200-M16 | 32 | 31 | 200 | 70 | 16 |

| MFT32-130-300-M16 | 32 | 31 | 300 | 130 | 16 |

| MFT32-150-350-M16 | 32 | 31 | 350 | 150 | 16 |

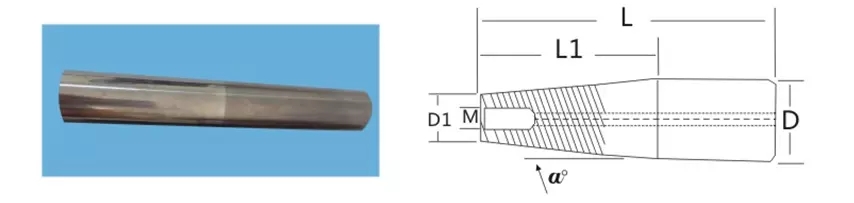

Customized Carbide Screwed Boring Bar

| Specification | D (mm) | D1 (mm) | L | L1 | M |

| MFT16-85-120-M8 | 16 | 15.6 | 120 | 85 | 8 |

| MFT16-95-150-M8 | 16 | 15.6 | 150 | 95 | 8 |

| MFT16-145-200-M8 | 16 | 15.6 | 200 | 145 | 8 |

| MFT20-40--100-M10 | 20 | 19.6 | 100 | 100 | 10 |

| MFT20-90-150-M10 | 20 | 19.6 | 150 | 150 | 10 |

| MFT20-140-200-M10 | 20 | 19.6 | 200 | 200 | 10 |

| MFT25-40-100-M12 | 25 | 24.6 | 100 | 100 | 12 |

| MFT25-85-150-M12 | 25 | 24.6 | 150 | 150 | 12 |

| MFT25-135-200-M12 | 25 | 24.6 | 200 | 200 | 12 |

Contact:

Hunan Benemetal Technology Co., Ltd

Add: No.88 Kaide Road, Hetang District, Zhuzhou City, Hunan

Province.

Tel: 0086-22599690

Whatsapp: +86-15060668009 +86-18974166960

Skype: lynnaaron

QQ: 349353634 1223240850 67192405

Email: lynn@carbideend-mills.com ,wei@carbideend-mills.com

Website: www.carbideend-mills.com